The air-carbon-arc gouging process removes metal physically. Gouging or cutting occurs when the intense heat of the arc between the carbon electrode and the workpiece melts the metal. Meanwhile, compressed air passes under the arc at 60-80 psi--fast enough to blow the molten metal away before the metal solidifies.

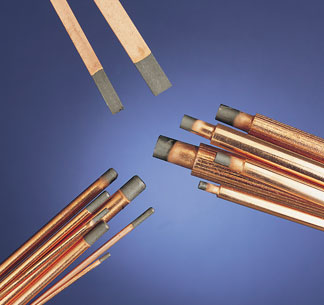

Our standard pointed 12" gouging electrodes come in these diameters: 1/8", 5/32", 1/4", 5/16", and 3/8". The 1/2" diameter is available in 12" lengths.

Our DC Copperclad Flat electrodes, available in two sizes, remove weld crowns and are used for scarfing applications.

Our Secur-Fit jointed electrodes are a fine mixture of carbon and graphite, allowing the rod to burn longer and remove more metal. When jointed, Symex copper to copper electrodes make nearly a perfect fit, providing constant electrode feed for greatly reduced stub loss.

Our jointed electrodes are available in 15" and 17" lengths.

| SYMEX DC COPPERCLAD POINTED* | |

|---|---|

| Part No. | Size |

| 81208 | 1/8 x 12 (3.175 x 305mm) |

| 81210 | 5/32 x 12 (4.0 x 305mm) |

| 81212 | 3/16 x 12 (4.8 x 305mm) |

| 81216 | 1/4 x 12 (6.4 x 305mm) |

| 81220 | 5/16 x 12 (7.9 x 305mm) |

| 81224 | 3/8 x 12 (9.5 x 305mm) |

| 81218 | 1/2 x 12 (12.7 x 305mm) |

| SYMEX DC FLAT COPPERCLAD | |

| 87224 | 3/8 x 5/32 x 12 (9.5 x 4 x 305mm) |

| 87240 | 5/8 x 3/16 x 12 (15.9 x 4.8 x 305mm) |

| SYMEX DC COPPERCLAD JOINTED | |

|---|---|

| Part No. | Size |

| 82720 | 5/16 x 17 (7.9 x 430mm) |

| 82724 | 3/8 x 17 (9.5 x 430mm) |

| 82732 | 1/2 x 17 (12.7 x 430mm) |

| 82440 | 5/8 x 15 (15.9 x 380mm) |

| 82448 | 3/4 x 15 (19.0 x 380mm) |

| ELECTRODE CURRENT REQUIREMENTS | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ELECTRODE | 5/32 | 3/16 | 1/4 | 5/16 | 3/8 | 1/2 | 5/8 | 3/4 | 3/8 FLAT | 5/8 FLAT |

| MIN. AMPS DC | 90 | 200 | 300 | 350 | 400 | 700 | 900 | 1100 | 250 | 300 |

| MAX. AMPS DC | 150 | 250 | 400 | 450 | 650 | 1000 | 1200 | 1500 | 450 | 500 |

| AIR REQUIREMENTS | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Compressor | |||||||||

| Torch | Part No. | PSI* | Air | Intermittent | Continuous | ||||

| *To convert PSI to KPA multiply by 6.895 | |||||||||

| Kg/cm | CFM | L/min | HP | (KW) | HP | (KW) | |||

| S-3 | 40024 | 80 | 5.6 | 27 | 765 | 5 | 3.7 | 7.5 | 5.6 |

| S-5 | 40040 | 80 | 33 | 27 | 934 | 5 | 3.7 | 7.5 | 5.6 |

| S-15 | 40005 | 80 | 5.6 | 27 | 765 | 5 | 3.7 | 7.5 | 5.6 |

| S-66 | 40036 | 80 | 5.6 | 50 | 991 | 7.5 | 5.6 | 10 | 7.5 |